Over the years we have built thousands of custom equipment solutions for a wide range of manufacturers, spanning a wide range of industries. Each time we engage in a new project, we have to address the issue of machine cycle time. This is the primary number by which customs gauge the overall Return On Investment (ROI), of a capital piece of equipment.

The tendency is to try and push a machine to produce at a higher rate of production, therefore, increasing the company’s overall throughput and reduce the overall time it takes to realize the return on the investment of that piece of equipment.

The primary issue with this philosophy, is that throughput is only one part of the overall equation necessary to understand the true value or ROI that a specific piece of machinery may offer.

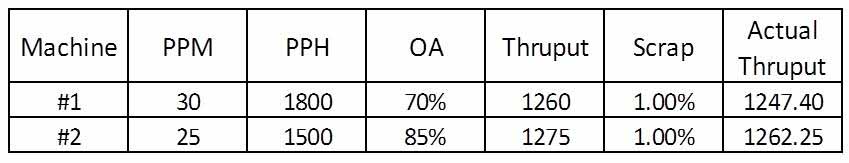

The following example illustrates this specific issue:

Even though machine #1 runs at a higher PPM (Part Per Minute) due to the lower OA, the #2 machine actually out performs it, even though the machine’s cycle time is almost 17% less PPM.

We have found that machines run best at a specific cycle rate. Once you push the machine’s cycle time over the threshold of capability, you start to see a drastic drop in overall machine uptime and thus overall throughput. This phenomenon is similar to a Formula 1 race car performance. These cars are pushed so close to the edge of technology and speed that a high percentage of the time, they don’t actually finish the race they started.

I have to deal with machine performances improvement everyday, I’m an automation engineer like many of you, so I developed a powerful tool for Android to get cycle time just tapping on a button, record every cycle time and export data. I hope you will find useful: *link removed*